In the heating industry, the demand of steam pipeline is increasing in recent years. With the increasingly standardization of urban construction, beautifying the city has become an inevitable development. The original overhead laying and pipe trench laying methods are gradually replaced by direct burial technology.

Due to the high temperature of the medium transported by the steam pipeline (generally 150 ~ 350 ℃), it brings many technical difficulties to the direct buried technology, such as expansion compensation, waterproof sealing, pipeline anti-corrosion, stress damage, local thermal bridge, whole line anti-corrosion, etc. After long-term technical exploration and research, and summarizing the reasons for the failure of domestic steam pipelines in the past, our company has formed its own unique product structure, and mastered the current domestic "internal sliding" and "external sliding" structure of the cutting-edge technology.

The technology of directly buried steam pipeline successfully provides reliable technical guarantee for the modern urban central heating pipe network with high requirements of city appearance and landscape, and makes the urban construction and environmental protection achieve harmony and unity. As the directly buried heating pipe network is hidden underground, it does not affect the traffic and urban landscape, so it is very popular with users and planning departments.

Performance index:

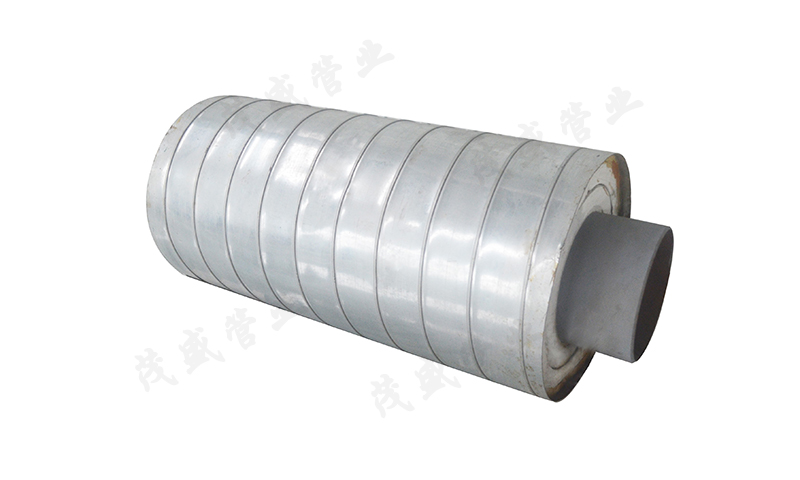

1. Aluminosilicate felt: drag reduction and shock reduction; Density: 96-140kg / M ³; Thermal conductivity: 0.09/400; Temperature resistance: 950-1350 ℃.

2. Hard calcium silicate: density: 220 + 10% kg / M ³; Thermal conductivity: 200 ℃ ≤ 0.067; Temperature resistance: 1050 ℃.

Product advantages:

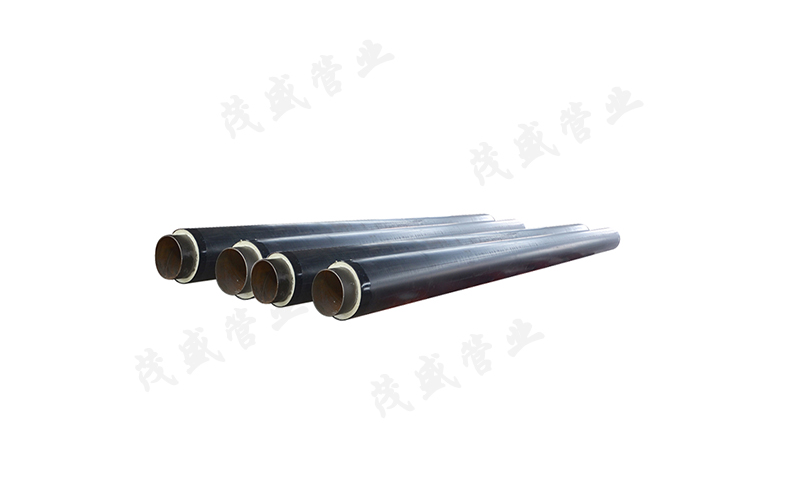

1. The product uses steel pipe as outer protective layer, which has the advantages of high strength, not easy to damage and good corrosion resistance.

2. It can reduce heat loss by 14-19% (compared with traditional overhead or trench laying).

3. It covers less land, does not affect the municipal planning, and reduces pollution. Especially in the construction of underground pipe network and areas with many obstacles, pipe communication is often required. However, directly buried pipes can pass through.

4. The installation is convenient and the construction period is short.

5. Long service life and low maintenance cost.

Structural features:

1. After the inner steel pipe reaches Sa2.5 (near white level) after shot blasting, inorganic zinc rich primer shall be applied to prevent the water vapor entering the insulation layer from corroding the inner steel pipe during construction.

2. A drag reducing layer wrapped outside the inner steel pipe can reduce the resistance of the inner steel pipe moving on the insulation layer.

3. The inner layer of thermal insulation material is wrapped on the inner steel pipe with microporous calcium silicate staggered seam, and the seam is filled with high temperature resistant and high elastic thermal insulation material, which effectively reduces the heat loss.

4. Polyurethane insulation material is selected for the outer insulation. The surface temperature of the outer protective layer is controlled below 50 ℃ by using the excellent insulation performance of polyurethane to protect the outer protective layer and increase the overall service life of the pipeline.

5. The radiation reflection layer is added between the two layers of thermal insulation materials to control the radiation loss of heat and make the steam pipeline more economical and reasonable.

6. The external protective coating of pipeline can be in various forms, including glass fiber reinforced plastic, casing with anti-corrosion coating, etc. the anti-corrosion coating has various forms, which can effectively protect the steel casing from groundwater erosion.